tear test for plastics|what is rubber tear test : wholesalers ASTM D1004 test method focuses on the tear resistance of flexible plastic film and sheeting at very low speed test rates of 51 mm/min (2 in/min). The test method uses force to initiate tearing. . Tear resistance of plastic film or sheeting is a complex function of its ultimate resistance to rupture. The specimen geometry and speed of testing .

Resultado da 31 de dez. de 2023 · Denver Broncos x Los Angeles Charges AO VIVO: onde assistir ao jogo em tempo real pela NFL | 31/12/2023 - VAVEL Brasil. .

{plog:ftitle_list}

WEBSorteio 12 horas 1º ao 10º. COMPARTILHE! O site Meu Jogo do Bicho faz a cobertura dos sorteios da Loteria Nacional do jogo do bicho, nossa equipe informa os números sorteados logo assim que o sorteio é divulgado. Aproveite e confira os sorteios das demais extrações da Loteria Nacional, basta clicar no link laranja:

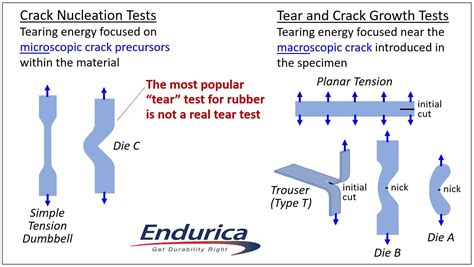

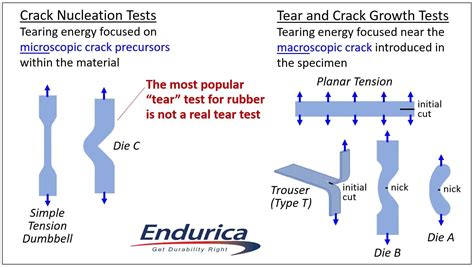

Tear resistance testing measures the force required to tear a polymerr test piece, from as small as a prepared cut or nick to a tear force completely across the width of a plastic or rubber material.

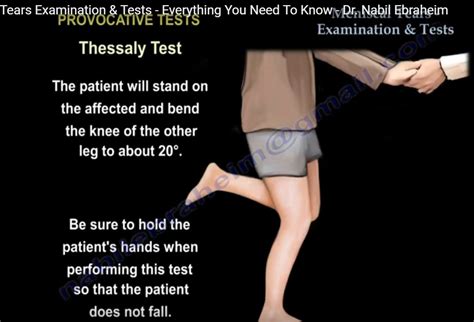

test for tear production

Plastics — Film and sheeting — Determination of tear resistance — Part 1: Trouser tear method . ISO 6383-1:2015 specifies a method of determining the tear resistance of plastic film or sheet less than 1 mm thick, in the form of standard trouser-shaped test specimens, tested under defined conditions of pre-treatment, temperature .We make a wide variety of equipment that will help you to perform tear tests – including specialized grips, fixtures and die cutters for proper sample preparation. . ASTM D2582 – Standard Test Method for Puncture-Propagation Tear Resistance of Plastic Film and Thin Sheeting; ASTM D5587 – Standard Test Method for Tearing Strength of .The specimen is then subjected to a tensile test at 2 in/min (51 mm/min) until complete failure. The specimen geometry and test speed are not intended to simulate real world tear conditions; instead, ASTM D1004 is intended to .

what is rubber tear test

1.1 This test method 2 covers the determination of the average force to propagate tearing through a specified length of plastic film or nonrigid sheeting after the tear has been started, using an Elmendorf-type tearing tester. Two specimens are cited, a rectangular type, and one with a constant radius testing length.ASTM D1004 test method focuses on the tear resistance of flexible plastic film and sheeting at very low speed test rates of 51 mm/min (2 in/min). The test method uses force to initiate tearing. . Tear resistance of plastic film or sheeting is a complex function of its ultimate resistance to rupture. The specimen geometry and speed of testing .

There are two types of plastic tear strength test: Elmendorf Tear (high speed pendulum test) Trouser Tear (low speed using standard tensile test apparatus). Elmendorf tear. The test piece is clamped and a cut introduced such that when the pendulum is released, a tear is propagated from the cut at high speed. The tear resistance is measured as .Tear testing provides information on the energy or force required to propagate a tear through a material. Tearing tests are commonly performed on foils, plastics, paper, and textiles. DDL has capability to perform many different types of tear tests, such as trouser tear, graves tear and the pendulum (Elmendorf) method.Tear strength or tear resistance is defined as the maximum force required to tear a test specimen in two different directions of stress and perpendicular to the stress direction. From: Subsea Valves and Actuators for the Oil and Gas Industry, 2021. . plastic films, paper and leather. Outdoor clothing and uniforms are examples of clothing . A quick video showing Universal Grip's scissor grips performing a tear test on plastic film using the Graves Tear Method. www.universalgripco.com

what does tear testing mean

types of tear testing methods

the Elmendorf tear test. It measures the average force required to propagate a tear through a . Tearing resistance of multi-layer plastic films 143 specified length of film or sheeting, and it is described in full in the ASTM standard D 1922-89 . RESTRICTED PLASTIC ZONE TESTS In order to limit the width of the plastic zone, we prepared .

Tear strength describes the resistance of a material to the expansion of a tear. The test setup is similar to a tensile test. The specimen is a trouser specimen or angle specimen with a defined tear length. . Adhesion tests on layers of plastic sheets and films according to DIN 53357 Method B (withdrawn), DIN 55543-5, etc. Device for .

ASTM D1922 Elmendorf Tear Test Scope: All plastic films and sheets are prone to tear with increased force. The ASTM D1922 test method is widely used to rank the relative tear resistance of thin plastic films and sheets. The pendulum impact tester determines the minimum force required for an existing slit to propagate through a [.]

Tear Resistance ASTM D1004; Tensile Set - Rubber - ASTM D412; Tensile Test Core (Flatwise) ASTM C297; Tensile Test Plastics - ASTM D638, ISO 527; Tensile Test Plastics - Thin Sheet ASTM D882; Tensile Test Plastics - Microtensile ASTM D1708; Tensile Test Plastics - ASTM D5766; Tensile Strength of Sandwich Constructions - ASTM C297 In the case of solid plastics, testing is typically performed by hitting the specimen with a hammer (Charpy or Izod impact tests). For films, a typical impact test is done with the free-falling dart method. Tearing properties of plastic films. The trouser tear test is most commonly used to measure the resistance of plastic films to tearing.These methods determine the tensile properties of plastics and plastic composites. This is done under defined conditions that can range from: pretreatment, temperature, humidity, and ; machine speed ; The test . 1.1 This test method covers the determination of the force necessary to propagate a tear in plastic film and thin sheeting (thickness of 1 mm (0.04 in.) or less) by a single-tear method. The method is not applicable for film or sheeting .

5.1 This test method is of value in rating the tear-propagation resistance of various plastic films and thin sheeting of comparable thickness. For highly extensible film or sheeting the deformation energy of the specimen legs is significantly greater than the tearing energy. The tear-propagation resistance in slightly extensible or non-extensible film or sheeting is distinguished .ASTM D1938 is the standard test for tear propagation in plastic films and thin sheeting. Manufacturers of plastics for consumer goods use this test to determine the integrity of the film and sheeting materials, as well as to determine if their products meet customer expectations. What Is ASTM D1938? ASTM D1938 test method measures the force necessary to propagate .

tested. Therefore, the tearing resistance is expressed in maximum newtons (or pounds-force) of force to tear the specimen. 5.4 The tear resistance of plastic film may be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Important factor that affects the tear properties of plastic. 1. The molecular weight of the polymer chains: Polymers with higher molecular weights have better tear resistance because they form stronger intermolecular bonds. This is because higher molecular weight polymers have longer chains that can entangle with one another, leading to tighter packing .

A test specimen, which has a single slit to produce two legs, see figure 1, is loaded into a tensile testing machine so that the slit is parallel to the axis of the machine and one leg is clamped in each jaw. The jaws are moved apart to tear the material by extending the slit until the tear has propagated to the end or an edge of the test specimen.A physical model of one of the principal end-use tests of film manufactured from linear low-density and low-density PE resins, the Elmendorf tear test (ASTM D1922, ISO 6383-2), is described. According to this model, the tear test of film is a special case of a high-speed stress/strain measurement performed on a polymer sample with a varying . Tear strength is simply the force it takes to rip a plastic film. Tear strength is commonly used for testing stretch film and other plastics. An Elmendorf tear test is commonly used to find the tear strength. One end of the sample stretch film is held in a fixed clamp and the other end is attached to a pendulum.

For example, with rubber, tear resistance measures how the test specimen resists the growth of any cuts when under tension, it is usually expressed in kN/m. [2] Tear resistance can be gauged via the same ASTM D 412 apparatus used to measure tensile strength, modulus and elongation.ASTM D 624 can be applied to measure the resistance to the formation of a tear .

tear testing techniques

Work with us to find the right equipment for your ASTM standard ASTM D1004 | Plastic Films | Tension Testing ASTM D1004 is a test method that determines the tear strength of flexible plastic film and sheeting at very low rates of loading using a constant-rate-of crosshead-movement type tensile testing machine. Tearing is producedDigital Elmendorf Tear Tester with TestWise™ software and touch screen. Supplied with easy to fit pendulum weights suitable for testing woven and nonwoven textiles as well as paper, plastic and other sheet materials. . plastic and other sheet materials. Brochure(s) ElmaTear . An extensive list of pre-loaded standards, organised by sample .Test no. Action; 1. Look at the sample. Is it transparent, translucent or opaque? 2. Feel the sample. Does it bend? Can it be scratched? What does the surface feel like? 3. Cut the sample with a sharp knife. Does it cut easily? Are the edges smooth or jagged? Does it crumble or flake? 4. Subject the sample to a float test. Does it float or sink?

tear resistance testing methods

Welcome to Betsson, home of great Sportsbook with live and .

tear test for plastics|what is rubber tear test